Industrial Gas Turbine Working Principle, MGT6100 and MGT6200

Industrial Gas turbine working principle:

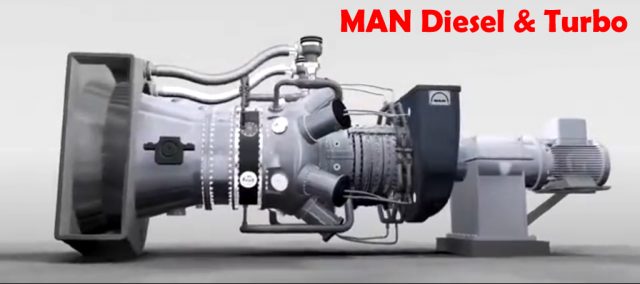

Industrial Gas Turbine Working Principle– with the MGT series from MAN Diesel & Turbo has created a family of industrial gas turbines that it has developed at its Oberhausen site. The highly efficient MGT6100 and MGT6200 Industrial Gas turbines set a milestone in the 6 megawatt output class.

Let us look at the MGT6200 Industrial Gas Turbine first. It is a twin shaft model used as a mechanical dry for compressors, for example, the compact core engine delivers a maximum output of 6.9 megawatts. This is equivalent to 9522 horsepower, thus as much as 95 automobile engines of 100 horsepower each produced together.

The MGT6200 Industrial Gas turbine basically comprises two sections, the gas generator with a high-pressure turbine on the left and the power or low-pressure turbine on the right which runs independently of the gas generator at a variable speed thanks to a second shaft.

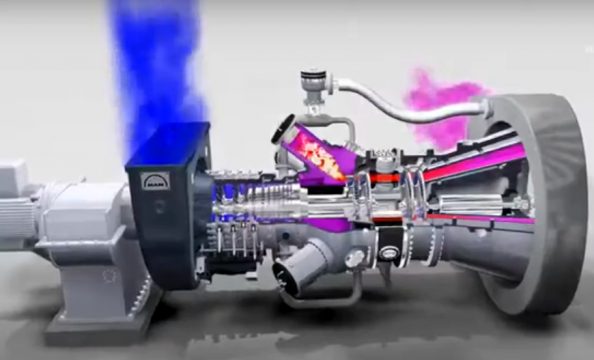

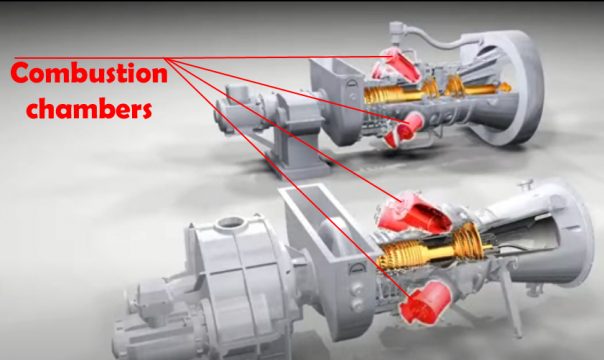

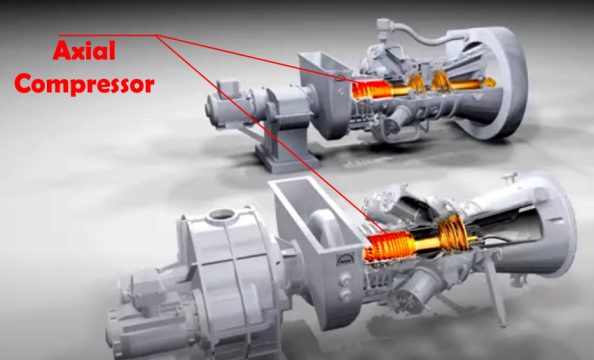

An external drive starts the gas turbine. In this case, it is an electric motor that drives the shaft of the high-pressure turbine and along with this, the 11 stages axial compressor mounted on it. The compressor driven by the high-pressure turbine serves to take in and compress the air needed for combustion inside the six combustion chambers. The air is mixed with fuel gas and the mixture is ignited, the hot exhaust gases expand driving both the high and the low-pressure turbines.

Top Portable Generators available on Amazon:

2000 Watt, Portable Generator, Gas Powered:

4750/3800 Watt Dual Fuel RV Ready Portable Gas Generator with Electric Start:

7500 Watt Dual Fuel Portable Generator With Electric Start:

*Please Note: These are affiliate links. I may make a commission if you buy the components through these links. I would appreciate your support in this way!

Let’s take a closer look at this process. Due to the spinning motion the blades of the axial compressor strike, the air they conducted into the turbine while compressing it. In the process a flow is created that passes through the air intake casing and then along the axis.

A pressure increase of 15bar means the air flows into the six combustion chambers with around 15 times more oxygen. These advance can combustors premix the fuel gas with the compressed air homogeneously already before it enters the chamber.

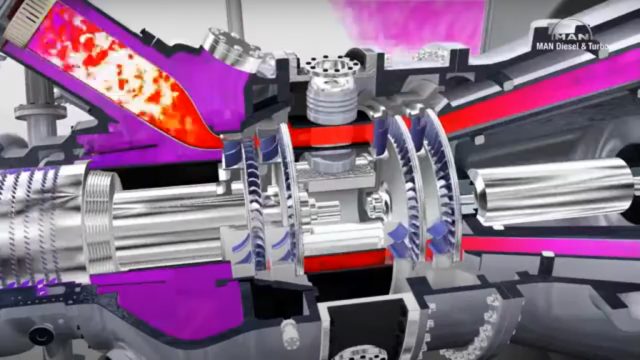

Afterwards this mixture is ignited and burns with extremely low emissions. The fuel gas air mixture expands due to the combustion heat to many times its volume as a result it flows at high speed, first through the two rows of blades of the high-pressure turbine.

Then through the low pressure or power turbine thus driving both shafts. The exhaust gases flow through a diffuser into the outlet casing their high temperature of around 460 degrees Celsius can still be utilized for instance to generate steam. The shaft of the power turbine can be operated independently of that of the gas generator in a speed range of 45 to 105 percent of the nominal speed of twelve thousand six hundred rpm and thus adapt optimally to the requirements of the machine to be driven.

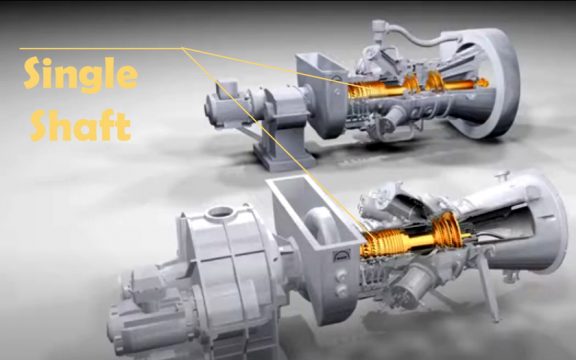

However such a flexible speed range is not necessary to generate power, that’s why MAN has come up with the MGT6100 Industrial Gas Turbine.

This single shaft model drives an electric generator at a constant speed and has been especially designed and optimized for this.

The MGT6100 Gas Turbine shares several modular assembly parts like for instance, the combustion chambers. Or

The Axial compressor with the MGT6200. But only one continuous shaft is used here. It saves on around 27% of components. It consists of seven thousand eight hundred forty six individual components.

While the MGT6200 is composed of ten thousand eleven parts. MAN Diesel & Turbo has been building Industrial gas turbines since 1988. The MGT series is the latest manifestation of this extensive experience. The company thus offers clean future ready drives for compressors and generators boasting high mechanical efficiency ratings of over 30% an extremely low pollutant emissions.