Transformer Tests: Transformer Factory Tests, Transformer Open and Short Circuit Tests

Table of Contents

Transformer tests, Overview:

Transformer Tests- in this article, you will learn about different types of tests which are performed on a power transformer. Since in an electrical power system a transformer play an important role, as transformer is used to step up and step down the voltage, so it is crucial to conduct transformer tests from time to time. The transformer tests are performed to make sure that the transformer is properly working and to reduce the chance of any failure.

Transformer Tests done at factory:

- Routine test

- Type test

- Special test

Routine tests:

Routine types of transformer tests are carried out in each job and can be classified as follows:

- Measuring of winding resistance

- Measuring of insulation resistance

- Separate source voltage withstand test (high voltage test on HV and LV)

- Induced overvoltage withstand test (DVDF test)

- Measurement of the voltage ratio

- Measuring of no-load and current

- Measurement of no-load loss and impedance (efficiency and regulation)

- Vector group verification

- Oil BDV test

Measuring of winding resistance “Transformer Winding Test”:

This test measures the resistance of the HV and LV winding. Winding resistance test includes assessing the condition of LV and HV winding. The transformer resistance is measured by using the current-voltage method. In this method test current is injected into the transformer winding and the voltage drop in the winding is measured.

By using Ohm’s law:

V=IR

Winding resistance can be measured. We will now perform the winding resistance test. Connect the leads to the tester. Connect the earthing connection of the tester with the transformer earth. Connect 1.1 lead of the tester to HV windings U terminal. Connect 1.2 lead of the tester with the HV winding V terminal. Connect the earthing connection of the tester with the transformer earth. Connect 2.2 lead of the tester to LV winding N terminal. Connect 2.1 lead of the tester with the LV winding of the U terminal. Start the test after checking the connection

The values of the resistance should be balanced for all three phases and should match the design values. The equipment used is a digital resistance meter.

Measuring the insulation resistance “Transformer Insulation Test”:

In this type of test, we measure the insulation resistance of HV and LV winding insulation resistance is basically resistance between the winding which are separated from each other. This test is performed with respect to the earth’s body and between LV and HV winding. When the insulation resistance of the transformer will be damage the two winding will become short and the transformer will be damage. This transformer test is performed so that we know the life of the transformer, the paper that we are using in the insulation, and the dryness of the paper. For this type of test insulation tester or megger is used. In digital megger, the DC voltage is generated which will be given to the winding during the testing time. In digital megger, we have a battery and a control switch with the help of a control switch we can increase or decrease the voltage. Recommended values are 2000 megaohms for HV and 500 megaohms for LV. We can set the megger value according to the chart which is given below:

| Voltage | Test voltage (DC) LV side | Test voltage (DC) HV side | Minimum R value |

| 415V | 500V | 2.5KV | 100MΩ |

| Up to 6.6KV | 500V | 2.5KV | 200MΩ |

| 6.6KV to 11KV | 500V | 2.5KV | 400MΩ |

| 11KV to 33KV | 1000V | 5KV | 500MΩ |

| 33KV to 66KV | 1000V | 5KV | 600MΩ |

| 66KV to 132KV | 1000V | 5KV | 600MΩ |

To perform this test we will first discharge the transformer and disconnect the leads on the LV and HV side. When performing this test do not touch the terminals of the transformer because we are giving high voltage through megger due to which the voltage is generated in the transformer. The insulation resistance value should be measured into 15 seconds to 1 minute of the service transformer. The transformer which is to be taken in use is known as a service transformer. When the insulation resistance of the transformer is to be the measure we perform three tests:

- HV to earth

- LV to earth

- LV to HV

Separate source voltage withstand test (high voltages on HV and LV):

This test checks the insulation property using the high voltage tester between primary and secondary between primary to earth, secondary to earth. A high voltage test is usually performed to qualify the device to operate safely during rated electrical conditions.

Procedure:

- The test should be carried in a dry place

- Apply the voltage value which is sufficiently low

- Gradually increase the voltage up to rated insulation value

- Maintained the rated insulation voltage for 60 seconds

- After 60 seconds gradually decrease the voltage value to zero

HV high voltage test:

HV of the transformer will be connected to a Potential transformer for supplying 50KV voltage. Supply 50KV to 33KV delta side of the transformer for 1 minute to check the withstand insulation capacity of the transformer high voltage winding. If the transformer withstands this voltage for 1 minute then the transformer passes the high voltage test.

LV high voltage test:

Now LV 11KV side is connected to a Potential transformer for applying 20KV voltage for 1 minute to check the insulation of the LV side.

Induced overvoltage withstand test (DVDF test):

This test checks the intern turn insulation strength of a transformer which is also known as the double voltage double frequency test. For an 11KV/433 V transformer, 866 volts are applied at the 433V winding because in this test we apply the double voltage so the double voltage for 433 is 866 with the help of a generator for 1 minute. If the transformer winding withstands this voltage then it passes the test otherwise the test will fail. Now to check the HV side similar process can be done by applying a double voltage of 11KV which is 22KV. Now as the normal frequency we use is 50HZ in this test we apply double frequency which is 100HZ. For the generation, we will use motor-generator set.

Measurement of Voltage ratio:

This test measures the voltage ratio as per the customer requirement of the transformer which has specified voltage rating on the primary side and the secondary side The voltage ratio is equal to the turns ratio in a transformer and we are conducting this test to verify the turns ratio of the transformer.

V1/V2 = N1/N2

Using this principle the turns ratio is measured with the help of a turns ratio meter if the value of voltage transformer ratio does not come within the limits we can now about the high resistance in leads of winding and top changer connection. If this correct the voltage ratio is assumed to be correct. The equipment used here is the turns ratio meter. Shortening between turns of winding can be detected by this test. So the three parameters are very important for the purpose of this test:

- Voltage ratio

- High resistance in leads of winding

- Shorting between the turns of the winding

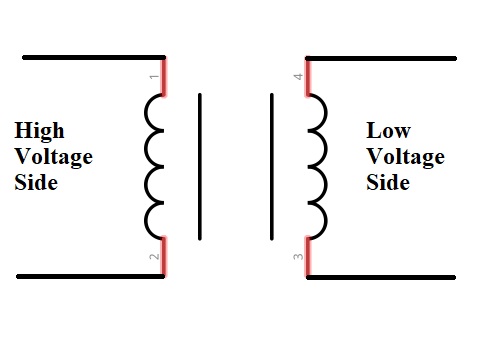

Single-phase diagram:

Low voltage injection to HV side

The test is done at a no-load position

Assume the voltage ratio is 6.6KV/433V.

Voltage ratio =6600/433=15.24 for the phase to phase.

Apply 415 V on the HV side if we get 27.23V from the LV side then the voltage ratio is correct as 415/27.23=15.24

Voltage ratio:

For testing we are considering delta to star connected transformer with 5 steps whose detail as below:

| Tap Number | HV voltage

(phase-phase ) |

LV voltage

(phase-phase) |

Calculated ratio |

| 1 | 6930 |

433 |

16 |

| 2 | 6765 | 15.62 | |

| 3 | 6600 | 15.24 | |

| 4 | 6435 | 15.86 | |

| 5 | 6270 | 14.48 |

Steps for transformer turn test:

- This test carried on no-load so first isolates the transformer from HV and LV side.

- Put the transformer at first tap or last tap so that you will get voltage ratio values in ascending or descending order.

- Connect the cables to the HV and LV side of the transformer for applying and measuring voltages. Make the connection without looseness.

Apply low ac voltage to the HV side of the transformer and measure the LV side voltage for the phase to phase and phase to neutral. The primary side of the transformer will be connected in delta and secondary winding of the transformer will be connected in a star so phase to neutral voltage will be 1/√3

- the phase to phase voltage for the secondary side.

- Repeat the test for the next tap up to the last tap and record the values.

- Check the voltage ratio error is within 0.5% or not.

Test result table:

| Tap number | Applied HV voltage (Phase to Phase) | LV voltage (Phase to Phase) | LV voltage (Phase to neutral) | Calculated ratio (Phase to phase) |

| 1 | 433 | 27.06 | 15.64 | 16 |

| 2 | 433 | 27.72 | 16.02 | 15.62 |

| 3 | 433 | 28.41 | 16.42 | 15.24 |

| 4 | 433 | 29.14 | 16.84 | 14.86 |

| 5 | 433 | 29.90 | 17.28 | 14.48 |

Now a day an electronic kit called TTR (transformer turn ratio) kit is available. By carrying out the test with this kit it will automatically show the turn ration or voltage ratio. So you do not need to measure the primary or secondary calculation of it.

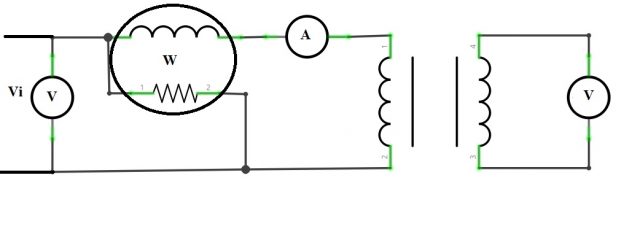

Transformer Open Circuit test:

The transformer is connected to the supply at the rated voltage and frequency namely the voltage and frequency given on the nameplate. The ratio of the voltmeter reading and V1/V2 gives the ratio of the number of turns. Ammeter A gives the no-load current and its reading is a check on the magnetic quality of the ferromagnetic magnetic and core and joints. The primary current on no load is usually less than 5 percent of the full load current in this test secondary winding of the transformer will be left open and no load will be connected with it and we will connect voltmeter with it. The I2 R loss on load is less than 1/400 of the primary side of the winding of the transformer. I2 R loss on full load and is therefore negligible compared with the core loss, the high voltage side will be open and the lower voltage side will be connected with the voltage supply. The core loss of the transformer can be measured by the wattmeter.

The no-load and iron losses are measured in the short circuit test. The 433V winding is charged at 433V supply the voltmeter is connected with it which will measure the supply voltage and the 11KV winding is left open. The power consumed by the transformer at no load is the no-load loss in the transformer the ammeter will be used to measure the current in the primary winding. The current which flows in the primary winding is no load current because no load is connected with the secondary winding. The current in the secondary winding will be zero as no load is connected at the secondary winding. So due to which less current will be flow in the primary winding. If a load is connected at the secondary side then the current that will flow in the primary side will be full load current. The no-load current is 2 to 5% of the full load current. For example, if the full load current will 100A then the no-load current will about 2 to 5 A. The wattmeter that will be used in the circuit will measure the losses of the transformer. This transformer will contain two types of losses:

Iron loss or core loss

Copper loss I2 R

The copper loss will be zero as the current is zero in the secondary side. As the current on the primary side is minimum, therefore, I2 R losses will be minimal and we will consider it is negligible.

The core loss will depend on the flux of the transformer. The flux will be generated due to the supply voltage. This flux will not depend upon the load the core loss will be constant. These core losses will be measure by a wattmeter. The ammeter will measure the I0 and the wattmeter will measure Pi.

Pi=Vi I0 cosΦ

cosΦ=Pi/(ViI0 )

The I_0 current will be of two types one will be I_w which is working current and the other is Iµ representing the magnetizing current.

R0=Vi/Iw

R0=Vi/(Iµ)

The effect of the actual frequency of the transformer must be taken into account. Equipment used is watt meters or power analysers.

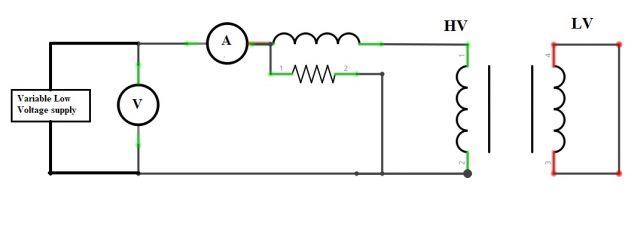

Transformer Short Circuit Test, Measurement of Load loss, and impedance:

In the transformer short circuit test, the secondary side of the transformer is short-circuited. The short circuit side will be a low voltage side which will be the secondary side and the high voltage will be the primary side. The wattmeter will be used to measure power. The ammeter will be used to measure the current. The voltmeter will measure the supply voltage. The low voltage side is short-circuited because if we short circuit the high voltage side large current will flow but we need less current to flow on the high side as the power remain constant the current will be maximum at the low voltage side. As the current will be minimum it will be easy for the ammeter to measure the current otherwise we will use other instruments for the measurement of high current. The supply voltage will be 2 to 5 % of the rated voltage. The variable low voltage supply will change slowly as we increase the voltage the current will also increase. We have to increase the current value to the full load current value. When we will obtain the full load current the transformer will start its operation. The secondary winding current will also become full load current then we will not vary the voltage.

Visc=Ic Ze

Pcf1=Visc IsccosΦ

As we have less voltage therefore we will neglect the core losses as it depends upon the voltage. As we have full load current so the copper losses will be present.

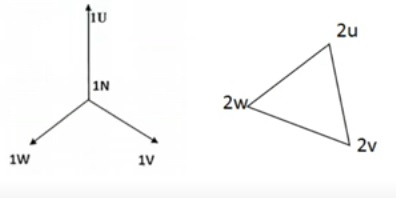

Vector group verification:

This test verifies the Dyn-11 vector group of a distribution transformer which is used for the parallel connection of the two or more transformer. For connecting transformers in parallel, the vector group must be the same otherwise we cannot connect the transformer in parallel. For example, the first transformer is Dyn1 type while the other transformer is Dyn11 type. When we connect this transformer in parallel the secondary of the Dyn1 phase angle is 30 while the phase angle of the secondary transformer is -30. When we do synchronization of both transformer then the phase difference will be 60 and it will not connect in parallel as a huge amount of circulating current will flow in it if we forcefully connect it. Due which its winding or insulation will damage. To avoid this condition we perform vector group tests. This type of test is usually performed in factories. Before starting this test we will make three equations. The first condition will be such that the phase of the first will be equal to the second, in the second condition the phase of the first will be either greater or less than the second, while in the third condition the sum of two phases will be equal to one phase. When we can make these three conditions we can perform vector group taste easily.

Here we first do a test on the Ynd1 type group. In Ynd1 the Yn represents HV winding connection whereas the d represents the LV winding. The number 1 represents the phase angle which is between the primary and secondary winding. The primary winding will be star connected and the secondary LV winding will be in delta connection.

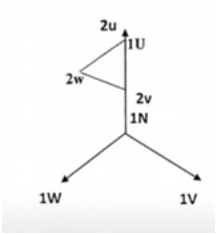

We will make three equations from the following diagram:

First, we will make “equal to” equation:

1U and 2V will be equal to 1U and 2W this is basically a triangle whose all sides are equal.

1U2V=1U2W

Greater than equation will be made by 1 U and 1V will be greater than 1U and 2V.

1U1V>1U2V

Now we will make summation equations 1U and 1N will be equal to 1U2V and 2V1N.

1U1N=1U2V+2V1N

So after preparing the equation we will 3 phases 415V to HV side winding. The voltage will be measured according to the equations. By using the first equation the probe will be first connected with 1U and 2Vand then connect the probe with the 1U and 2W. Note that whether both the voltage is the same or not. This process can be applied to the remaining equations. When the values obtain the satisfy the equation then the vector group test will be completed.

The Vector group means angular displacement between HV and LV of the same phasor, for example, capital R and small r. The equipment used here is a voltmeter.

Oil BDV test:

Oil breakdown voltage is checked as per IS-335. This includes:

- 100mm L × 70mm B × 80mm HT glass pot

- 5000ml oil sample

- Spherical electrodes with a gap of 2.5m

- The recommended value is 60KV

Dielectric strength test of transformer:

This test is performed on the oil of the transformer. The requirements for the oil of the transformer are:

- The strength of the dielectric of the oil should be high. The dielectric means that when a unit thickness of the insulated wire withstands voltage which is known its dielectric strength. The dielectric is the insulation strength of the material.

- It should have the capability of transferring heat as the winding of the transformer is inside the oil and the losses which occur such as iron loss, a copper loss which occurs in form of heat. So the transformer oil must have the property to absorb this heat and dissipate it in the surrounding by sending it into the transformer tank.

- It should have low viscosity due to which its heat transferring capability will be decreased.

- The transformer oil prevents the coils from the corrosion.

- It should be chemically stable.

When the temperature increases the dielectric strength of the transformer decreases as the operating time of the transformer is maximum due to which maximum heat will be generated. The moisture can also affect the dielectric strength of the transformer. To perform the test we will do the following steps:

We will take a container that will be fitted with the two electrodes. The diameter of the electrode should be 13mm and connect both electrodes with the transformer. We will set the proper gap between both electrodes which should be 4mm. The oil in the container should be 80mm and the electrodes should be in the middle of the container. Then we will supply the voltage through the transformer. The voltmeter will be used to measure the voltage between the two electrodes. We will increase the voltage until a spark appears between the two electrodes. The point at which the spark will appear will be the breakdown voltage at which the voltmeter reading will be zero and we will note that voltage. This will be the dielectric strength of the transformer.

Transformer Tests done at Sites:

- Pre-commissioning site

- Periodic condition-based monitoring test

- Emergency test