Carbon Resistor Vs Metal Film Resistor: Carbon Composition and Carbon Film

Table of Contents

Carbon Resistor Vs Metal Film Resistor, Description:

Carbon Resistor Vs Metal Film Resistor- in this article you will learn in detail about the Carbon composition resistors and Metal Film resistors. Read my previous articles on

Carbon composition resistor:

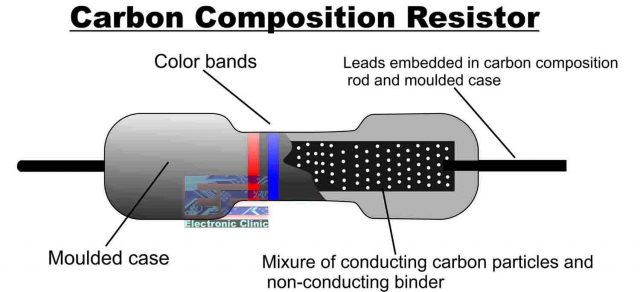

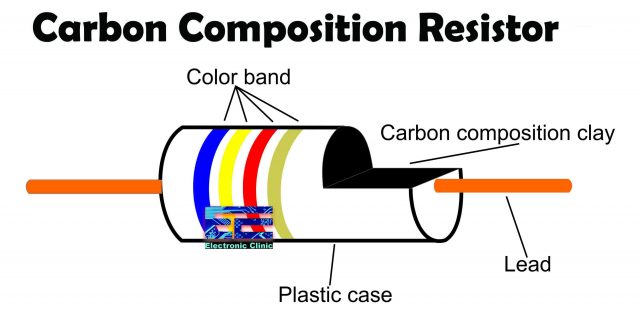

It is a typical fixed resistor made from the mixture of granulated powdered carbon or graphite insulation filler or a resin binder. The insulating powder binder is made in the shape of rods and there are two metal caps on the both ends of the rod. There are two conductor wires on the both ends of the resistor for easy connectivity in the circuit via soldering.

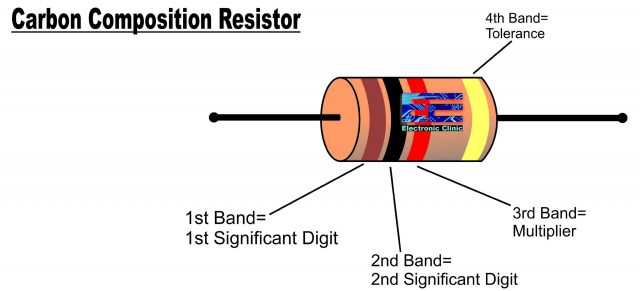

A plastic coat covers the rods with different color codes printed, which denote the resistance value. For the resistor coding read my article “ 4 Bands and 5 Bands Resistor color codes explained “.

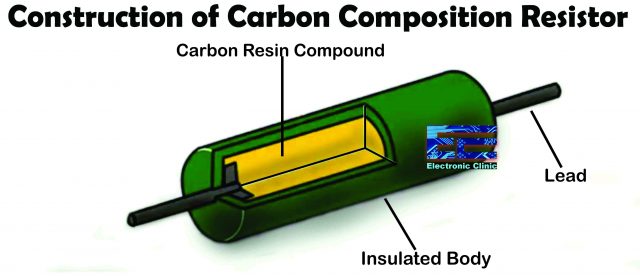

Construction of carbon composition resistor:

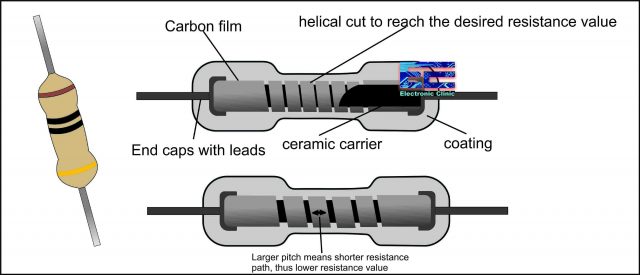

The carbon composition resistors are made from a solid cylindrical resistive element with imbedded wire leads with metal end caps. The cylindrical resistive element of the carbon composition resistor is made from the mixture of carbon or graphite powder and ceramic made of clay. The carbon powder acts as the good conductor of electric current. The solid cylindrical resistive element is covered with plastic to protect the resistor from outside heat. The leads are made of copper adjoined at two ends of the resistive element.

Availability of carbon composition resistors:

They are available in one ohm to 25 mega ohms and in power rating from one quarter watt to up to five watts. Factors affecting resistance of the carbon composition resistors. Resistance of the carbon composition resistor depends on three factors.

-

Amount of carbon added:

The resistance of the carbon composition resistor is inversely proportional to the amount of carbon added.

-

Lengths of solid cylindrical rod:

The resistance of the carbon composition resistor is directly proportional to the length of solid cylindrical rod.

-

Cross sectional area of the solid cylindrical rod:

The resistance of the carbon composition resistor is inversely proportional to the cross-sectional area of the cylindrical rod.

Applications of carbon composition resistors:

- Carbon composition resistors are suitable to withstand high energy pulses while having a relatively small size.

- The carbon composition resistor is used in DC power supplies.

- It is used in the power control circuits.

- It is used in test equipments.

- It is used in computers.

- It is used in current-limiting circuits.

- It is used in high voltage power supplies.

- It is used in welding control circuits.

- It is used in surge protection circuits.

- It is used in general-purpose electronics equipments.

- It is used in high frequency applications.

Advantages of carbon composition resistor:

- The major advantage of carbon composition resistor is its ability to withstand at high energy pulses.

- The cost of carbon composition resistor is low.

Disadvantages of carbon composition resistor:

- For stability poor stability is the major disadvantage of carbon composition resistor. Even within a short period resistance of carbon composition resistor will change rapidly.

- Generate high noise.

- Low accuracy.

- The most common problem occurred in the carbon composition resistor is water absorption. When the carbon composition resistor absorbs water the resistance may increase a decrease.

Carbon film resistors:

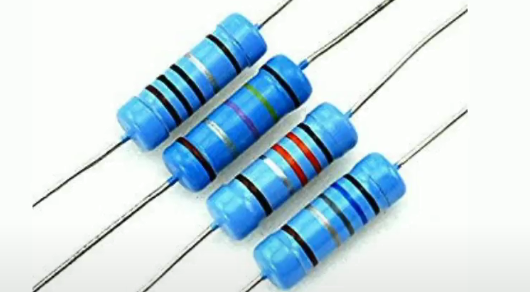

The carbon film resistors look like these, all are the carbon film resistors. We use the carbon film resistor in various places. There are different types of the carbon film resistors with different values. The carbon film resistors are mainly used in the frequency circuits.

Inside the carbon film resistor, it’s looked like this. In the middle there is one glass tube. As per the glass tube there’s one coatings of the ceramic, on that coating there is carbon film is oriented upward is oriented on that glass tube. The land of this carbon films is increasing the value of resistance in a resistor. All the value of the resistor depend upon the value or the length of that carbon film. If we increase the length of this carbon film so the resistance of that resistor is also increases. When we increase the width of that carbon film, so the value of resistance is decreasing. So, this while the carbon film resistor we can say the carbon film resistor because there’s orientation of the carbon film inside the resistor and most not this that we used this resistor in the signal circuits because it giving the clear result.

Metal Film Resistor:

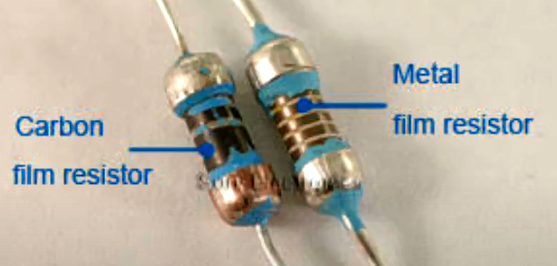

Metal film resistors are axial resistors with the thin metal film as resistive element. The thin film is deposited on usually a ceramic body or the resistor which uses metal film to limit the flow of electric current to a certain level is called metal film resistor.

Construction of metal film resistor:

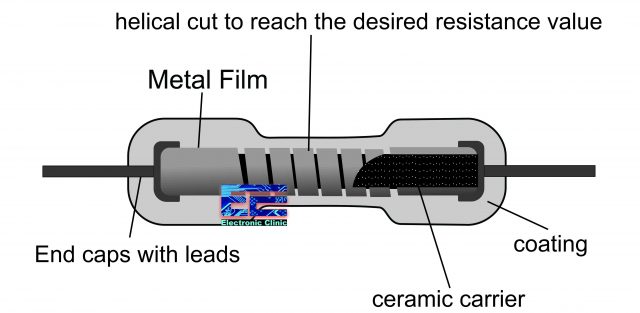

The resistive element is a thin metal layer that is usually sputtered on a cylindrical high purity ceramic core.

For the better accuracy of the metal film resistors, a unique method is used in which the deposited metal is aged artificially by keeping it for a long period at a low temperature.

Normally Nickel chromium (NiCr) is used as the resistance material, but in some special applications other alloys are also used such as antimony and tin, Platinum with Gold, and tantalum nitride.

The resistance and stability are fully dependent on the thickness of the metal film. Usually it seen that the larger thickness of the layer results in a better stability and a lower resistance value on both ends. A metal cover is pressed with the connection leads, after this the desired resistance is achieved by cutting a spiral shaped slot in the thin metal layer.

Availability of metal film resistors:

In the market metal film resistors can be easily found with tolerances of 0.1, .025, 0.5, 1 and 2%.

Usually the metal film resistors have resistance and temperature coefficient between 10 and 100 ppm/K.

Factors affecting resistance of metal film resistors:

The resistance of the metal film resistor depends on:

Metal film layer:

The metal film resistor resistance is inversely proportional to the thickness of the metal film layer.

Widths of helical metal film cut:

The resistance of the metal film resistor is inversely proportional to the widths of helical metal film cut.

Advantages of metal film resistor:

- Low cost

- Generates less noise than carbon composition resistor

- Wide operating range

- Long term stability

- Low tolerance

- Low temperature coefficient of resistance hence the resistance of the metal film resistors does not change easily with change in temperature

- Very small in size

Applications of metal film resistor:

- High frequency applications

- Active filters

- Bridge circuits

For video tutorials, visit my YouTube channel “Electronic Clinic”.