Estimate of Residential Wiring

Estimate of Residential Wiring

Before estimating residential wiring, every electrical engineer or estimator must have a thorough command of all rules and regulations of electrical wiring. Moreover, the details provided by an architect in drawings of the proposed building should also clearly be understood. After getting blueprints from an architect, an estimator or contractor designs a plan, and all the necessary details about the proposed wiring project are collected. After which, he prepares an estimate, which includes information about wiring materials (i.e., batten or conduit length, cable length, and other accessories required for the completion of wiring, etc.), their cost, wiring related accessories (i.e., switches, sockets, and holders, etc.) and apart from their cost, labor costs.

Necessary Instructions for Preparing the Estimate of Residential Wiring

Before preparing an estimate of residential wiring, the following information or instructions must definitely be inculcated into mind;

(1). If the height of a building is not known, then the minimum height is assumed to be 3.5 meters whereas the maximum height is 4 meters (13 feet).

(2). In a building layout, horizontally spread wires are always illustrated instead of vertically spread wires.

(3). At the time of preparation of an estimate, measurement of vertical wires has also to be taken, just similar to the measurement of horizontal wires. The measurement of these wires is done according to the height of the building (it is taken as 0.5 meters if the roof height is 3.5 meters and as 1 meter in a situation of a roof height of 4 meters).

(4). The measurement of wires has always to be carried out according to the scales given on the building map. However, if scales have not been provided in maps, then the scale will be presumed as 1:100 (i.e., a distance of 1 cm will be treated as 1 meter).

(5). A socket outlet should be installed at a minimum height of 20 cm and a maximum height of 30 cm from the ground.

(6). At least two sockets should be available in a 3×3 meter (i.e., 10 x 10 feet) room. Remember that one socket is counted as a half-point.

(7). The number of socket outlets in a drawing-room and TV lounge is intentionally retained high.

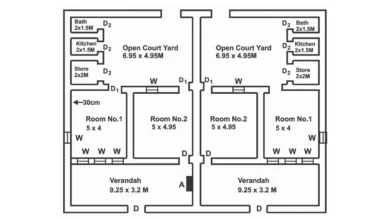

(8). The height of a switchboard from the ground should be 1.5 meters (5 feet). See figure 10.1.

(9). The height of a distribution fuse board from the earth should be 1.75 meters (6 feet). Remember that fuse and main switch are installed on the same distribution fuse board.

(10). Nowadays, circuit breakers are generally used instead of a switch and fuse, which are installed on a panel board instead of a distribution fuse board (DFB).

(11). The height of the wiring, lamp, and tube from the switchboard should be 1.25 meters (4 feet).

(12). If the height of a roof is greater than 4 meters (13 feet), even then the height of the wiring as well as switchboard remains constant.

(13). The height of wiring, lamp, and tubes from the floor tend to be 2.75 meters (9 feet).

(14). For making a connection in a distribution fuse board, every wire is spaced apart 0.5 meters and for a switchboard, it has to be 0.25 meters extra.

(15). For making a connection of lamps, tubes, fans, and other electrical

appliances, a 10 cm extra wire must essentially be left in a holder, ceiling rows, and fan box.

(16). The width of room doors generally ranges from 1 meter to 1.07 meters (i.e., 3.28 feet to 3.5 feet), whereas the bathroom door tends to be 0.6 meters (2 feet) wide.

(17). The switchboard is generally installed at a distance of 0.25 meters (10 inches) from a door. However, if the door is located in a corner of any room, the distance of the switchboard from the corner should be 1.5 meters (i.e., 0.25 + 1 + 0.25 meters).

(18). A distance of 5 cm (12 inches) is retained between clips on a batten during a batten type of wiring.

(19). In order to install batten on a wall, 1 1/2″ screws are plugged into the wall and their mutual distance tends to be 1 foot or 3 screws per meter. However, screws are compulsorily mounted on the batten ends at a distance of 1″.

(20). For ceiling rows and holders etc., 1/2″ screws are mounted.

(21). For installing tube lights, screws of 2″ size are fixed.

(22). For installing regulator and fuse, 3/4″ size screws are used. However, in the situation of using a fan dimmer instead of a regulator for a ceiling fan and using a piano-type fuse instead of a conventional fuse, screws are already available in them.

(23). For the installation of a switchboard, 4 pcs of 2 ½ ” size screws, and for the installation of a round block, 2 pcs of screws are used.

(24). While taking a batten estimate, if the number of wires is 6, then a double batten of a half-inch i.e., 1/2” size will be applied. If the number of wires is 7 or 8, then one batten of 3/4″ size and another batten of 1/2″ size will be used together. However, if the number of wires is 9 or 10, then in such a situation, a double batten of 3/4″ size will be used. Remember that normally only these two batten sizes (i.e., 1/2″ and 3/4″) are used.

(25). As fan boxes are used for hanging fans under a concealed wiring system, therefore, there is no need of mounting any ceiling rows. However, in other types of wiring, a hook is generally used for hanging a fan.

(26). The maximum number of switches and screws on a wooden board is as below;

| Size of Board (in Inches) | No. of Switches | No. of 3/4″ Screws |

| 4 x 4.5 | 2 to 3 | 4 |

| 7 x 4.5 | 5 | 4 |

| 10 x 4.5 | 8 | 6 |

| 13 x 4.5 | 11 | 8 |

(27). If the number of switches is large, then an 8″ x 10″ size board or 10″ x 12″ size board is used. It should, however, be inculcated in mind that in the case of concealed wiring, a Bakelite sheet is covered on a wooden frame, and the depth of the frame tends to be maximum. During the process of estimation, prices of both (i.e.

Bakelite as well as a wooden frame) are counted separately. As the depths of the frames used in other types of wiring tend to be less as compared to the concealed wiring, therefore, instead of using separate frames, wooden boards are generally used.

(28). In the situation of a direct lighting system and indirect lighting system, the quantity of utilization factor is taken as 0.4 to 0.6 and 0.1 to 0.4 respectively.

(29). Wherever too much dirt and dust are found (i.e., courtyard, verandah, and outer room, etc.) the quantity of depreciation factor is taken as 0.5 at such places, whereas for places with low dirt and dust e.g., interior rooms, the quantity of depreciation factor is taken as 0.6 to 0.8.

(30). The length of a required conduit /batten is calculated according to a plan of the building (where wiring is proposed to be done).

(31). Keeping in view the chances of wastage, a further 10% share of the total calculated length of every wiring system, is included.

(32). A wire’s length is calculated with the help of the total length of batten/conduit obtained, after the inclusion of wastage.

(33). For a looping system, the length of a wire is taken as 2.5 times the length of a conduit, and for a junction box system, 2 times.

(34). The length of an extra wire or looping wire left in the switch boxes, should never be less than 0.5 times the height of a box.

(35). The length of a wire to be used for making a connection from a mainboard to the meter board, should not exceed 7.5 meters, and its size should be one size higher than the actual size of the selected wiring cable.

(36). A clearance (distance) of about 0.25 to 0.5 meters is generally taken between the place of wiring on a wall and roof. However, this depends on the type of building and the crossing of the beam.

(37). All sub-circuits must have their own distinct continuous earth continuity wire.

(38). The light wiring and power wiring should be segregated from each other right from the starting point of supply. Wires of both should never be run in the same conduit.

(39). There is no need for a consumer to provide separate earth for his lighting loads and the supplier’s earth is sufficient for the purpose.

(40). All wall plugs should be three-pinned and properly earthed.

(41). Wires of more than three circuits, should never be left in a switch box without a connection. A separate box should be provided for each circuit.

(42). The labor charges of any laborer can be obtained by multiplying his per day wages with the number of his working days.

(43). The approximation of transport charges can normally be done through the length of the route and the type of available transport. However, transport charges should not exceed 5% of the material costs.

(44). Normally, overhead charges from 10 to 15 percent of the total costs are included in the project estimate. Tool charges are also included for large installations, which tend to be 3 to 5 percent of the total costs.

(45). The wiring of all multi-storied buildings higher than 15 meters, should be carried out according to the preset rules & regulations, and it should be duly examined by an electrical inspector.

(46). A 25 years age of every type of wiring system should be kept in mind. For the achievement of this objective, top-quality material should be used. Educated contractors and skilled workers should be hired for installation. However, in such a situation, labor costs and material costs will certainly go up.

(47). In case the load is higher than 4 KW, an arrangement of a three-phase supply should be made.

(48). A switch-controlled three-pin plug point should be provided on every switchboard, having one of its pins properly earthed solidly.

(49). A consumer has to provide one earth electrode for a single-phase supply and two earth electrodes for a three-phase supply in his premises.

(50). A galvanized iron or coated copper wire having a size of 14SWG, should be used for earth leads.

(51). All non-current carrying metal parts should be earthed through two separate earth wires.

(52). All non-electric metal works installed in a bathroom e.g., bathtub, water pipe, sink, etc., should be closely connected and earthed.

(53). A sub-circuit should not have more than 800 watts load or a maximum of 10 lights or fans should be installed on a single sub-circuit. In a situation of power sub-circuit, the load of every power circuit remains limited up to 3000 watts.

(54). The number of plug points in every circuit of a power circuit, should not exceed 2.

(55). A best-quality flexible insulated cable should always be used for all types of household electrical appliances.

(56). Pump motors should not be installed under an open sky without a cover, so as to protect them against inclement weather conditions.

(57). The earth leakage circuit breakers should always be provided for any loads exceeding 5 KW.

(58). Keeping in view the modifications and capacity enhancement requirements in the future, every wiring circuit should be designed to support an additional load from 10 to 20 percent.

(59). There is no need to fit a switch or fuse on a neutral wire and earth wire.

(60). On the entry point of a consumer’s premises, a circuit breaker or a fuse and a link switch should always be installed on every phase conductor of the main supply.

(61). The selection of wire or cable’s current rating should always be done according to the requirements of loads.

(62). All the main switches must be enclosed in an insulated or metal box and they should be fixed on the supply entrance paths.

(63). The spot of installation of a mainboard should be such that easy access can always be possible to it during situations of emergency.

(64). A locked facility should be available for the protection of the main switchboard, so that unconcerned persons cannot open it.

(65). A proper lighting arrangement should be available around the working places nearby the indoor switchboards.

(66). Every circuit or apparatus should be connected separately to the switch.

(67). When wiring has been completed, then a test should be conducted to check its leakage before the release of supply. The maximum current of leakage value loads should not exceed 1/5000.

(68). The ceiling rows are not used in a circuit the voltage of which exceeds 250 V

(69). Every 15 A socket outlet for residential electric appliances should be of control type, and there should be a separate fuse for it.

(70). Every ceiling fan should be controlled through a regulator, and a switch or dimmer fitted on a series.

(71). For All large buildings, having been provided with a three-phase supply, the load distribution on all phases should be equivalent.

(72). An estimator should certainly keep every necessary item in his mind for the purpose of carrying out an estimation.

(73). After the distribution board, the same size conductor should be used in the entire building.

(74). For batten wiring system, C.T.S or T.R.S wires, whereas for conduit wiring, PVC insulated wires are used.

(75). Every sub-circuit must start from the distribution fuse board (that’s every sub-circuit must be connected to the distribution fuse board). For every light and main sub-circuit, only a three-pin 5A socket outlet, whereas a three-pin 15 A socket outlet is used for all power sub-circuits.

(76). The elevation of socket outlets in a bathroom should never be less than 1.5 meters.

(77). A light and a 15A socket are a must for use in any ordinary type kitchen. However, for a small-sized kitchen, a light point and a 5A socket should necessarily be available in it.

(78). The main switch should be installed in an outward verandah. So that one cannot peek into the house, meters can be protected, and a meter reader can access it easily.

(79). The size of the applied conductor should be such that a load current could transmit safely through it.

(80). An additional load should never be exerted on any available installation until it is firmly believed that this installation can tolerate such an additional load safely.

(81). In a situation of excess current flowing as a result of a failure of overload or insulation, every sub-circuit can be protected through a circuit breaker or a fuse.

Sequence To Be Followed in Carrying Out the Estimate

For estimating the value of required material and its costs under the conduit wiring system, the following sequential process should be adopted.

(1). Drawing of Installation Plan

First of all, a feasible plan of the building is drawn with the help of a suitable scale, and electrical points, switchboards, mainboards, energy meters, main switch and distribution boards, etc., are marked on the plan through some specific electrical symbols. The wiring path, making a connection from every point, is being represented by drawing a relatively thick single line.

(2). Calculation of Total Connected Load in Amperes

The basic objective behind finding out a calculation of full load in any building is actually to determine the ratings of service cables and the main switch of an energy meter.

(3). Selection and Rating of Main Switch and Sub-Main Switch

After estimation of the total available load, the main switch can easily be selected in the market based on the current rating and the number of poles.

(4). Selection & Rating of Main Distribution Board

The main distribution board is a type of fuse box, wherein the sub-circuits installed in the entire building, are connected together. Apart from 15 Amperes rating power sockets, the selection of the main distribution also depends on the total number of points in a building.

(5). Calculations for Length of Conduit Pipe

The calculation of the length of a conduit pipe is carried out very carefully in the following three stages.

(i). During the first stage, conduit proposed to be installed from switchboard to HR or horizontal run, and which also includes a distance from the distribution board to HR, is calculated.

(ii). During the second stage, conduits set on walls under the roof lying parallel to the floor, are calculated.

(iii). In the third stage, the conduit installed between HR and roof, is calculated.

The total of all conduits explained in the aforementioned three stages is summed up. Then 10 percent wastage allowance is added to this total to determine the total length of a conduit required for the building.

(6). Calculations for Length of Phase Wire and Neutral Wire

The calculation of a phase wire and a neutral wire is done separately for each sub-circuit. For example,

Sub-circuit no. 1: Phase wire and neutral wire

Sub-circuit No. 2: Phase wire and neutral wire

After the calculation of neutral and phase wires required for sub-circuits available in the entire building, the lengths of phase, as well as neutral wires, are calculated to draw out total phase and neutral wires. Then 15 percent wastage is also added to this wiring required for the building. As such, the final total length of wires which is required for the building is determined.

(7). Calculation of Length of Earth Wire

In the case of batten wiring, earth wire is also installed along with other wires on the batten. However, in a situation of metal conduit wiring, no separate earth wire is run along with a conduit, rather metal conduit is earthed itself and used as an earth wire. In the concealed PVC conduit wiring, earth wire is also run along with other wires in a conduit just similar to the batten wiring system. Most often, after calculating the length of total earth wire, the length of the earth wire is converted to weight at the time of entering it in the material table.

(8). Preparing Material Table

Finally, a material table is prepared, wherein the detail about every item has to be mentioned extremely cautiously.

Note: In batten wiring system, apart from a difference in the calculation of a wire’s length, the aforementioned sequence has to be kept into consideration as well for the purpose of estimation. As batten can be found in different sizes, therefore, first of all the lengths of different sizes of batten are calculated in batten type wiring. Then it is multiplied by the number of wires, which can be fixed or supported by this batten.

Next Topic: Batten Wiring Estimates

Previous Topic: Importance of Tables Used in Planning & Estimating

For electronics and programming-related projects visit my YouTube channel.

Your needs come first! Purplewaveindia has no agendas, and no loyalties to anyone other than you, our client. Purplewaveindia was established in 2018. And in a short span of 4-years, Purplewaveindia has become one of the prominent players in the Indian Audio Video Manufacturing and Integration Industry.