Gas Turbine Power Plant and Types of Gas Turbine

Table of Contents

Gas turbine Power plant:

A gas power plant burns natural gas to generate the electricity. As the name suggest the gas power plant is operated by using gas. Gas is the operating medium of gas turbine which rotates the prime mover. The gas can be of any type it can be simple air or natural gas or it can be non-reactive mixture of gases. Gas power plant or natural gas power plant works on brayton cycle to generate the electricity. Natural gas plays a big role for generating electricity. This plant is more flexible for power generation; it is more efficient per ton of fuel. Natural gas turbines were first introduced for public use in 1939 to 1940 at a plant in Nicoya Haidle Switzerland. Gas power plant generates a quarter of world electricity and significant part of global greenhouse gas emission like carbon dioxide, methane, nitrous oxide, ozone and water vapour.

Gas power plant is type of fossil fuel power plant in which chemical energy is stored in natural gas which is mainly methane is converted successfully into the mechanical energy and electrical energy. All gas power plants use gas turbines. The overall efficiency of the gas turbine power can be about 35 % almost the same as the conventional steam power plant.

Operation of the Gas power plant:

Natural gas is added along with stream air which combust and expense through turbine causing a generator to spin a magnet making electricity. The turbine is used to generate drive a synchronous generator which produce the electric power because the turbine normally operates at very high rotational speed of 12000 rpm or more it must be connected to generator through a high reduction gear since the generator runs at speed of 1000 or 1200 rpm depending on the ac frequency of electricity grid.

A gas turbine is a heat engine and a turbo machine which is used generally for electrical power production in gas turbine power plants. The gas turbine is heat engine that will convert heat energy in to mechanical energy.

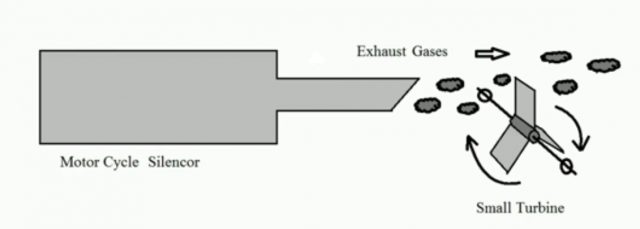

Now to understand the operation of the gas turbine power plant we will consider silencer of the motor cycle from which exhaust gases are come out with energy contain having some velocity and if we place small turbine in front of it when these exhaust gases fall on the blades of the turbine. It will start rotating in corresponding direction.

Now understanding this experiment the working of the gas power plant is similar to it.

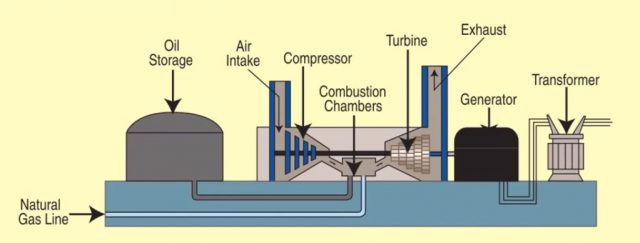

Components of the gas turbine:

Air compressor:

The air compressor and turbine or mounted at either end on a horizontal axle shaft with the combustion chamber between them. The main work of the air compressor is to compress the air and increase its pressure.

Combustion chamber:

In the combustion chamber the compressed air combines with fuel and the resultant mixture is burnt. In some cases the liquid fuels are also used but mostly the gases are used as fuel. A spark plug is used for the ignition to burn the mixture of gas. The air compressor and combustion chamber is also called gas generator because it produce hot gases.

Turbine:

The burning gases expand rapidly and rush into the turbine where they cause the turbine wheels to rotate. The shaft of the turbine is coupled to generator to drive it. To increase the efficiency of the gas turbine multistage gas turbine can also be used.

Types of gas turbines:

There are the following types of the gas power plant:

Open loop gas turbine:

This is also known as simple gas power plant. A hot gas drives a gas turbine to generate electricity. This type of power plant is relative cheap to build and start very quickly but due to lower efficiency. Simple gas turbine power plant is able to dispatch faster than coal fired power plant. They are turn on or off faster in order to meet the society electricity needs often needed on the grid fluctuating electricity needs of society known as peaking power. The combined cycle gas turbine power plant consists of simple cycle gas turbine which used the brayton cycle followed by a heat recovery stream turbine and generator which use the Rankine cycle. The most common configuration in to gas turbine supporting one stream turbine. They are more efficient than simply cycled plant and can achieve efficiency slightly over 60 % and dispatch times of around half an hour. It makes use of the hot exhaust gases that would otherwise be dispelled from system. The open loop gas turbine consists of three main components:

- Compressor

- Combustion chamber

- Turbine

The rotor of the turbine and compressor is connected by the shaft. One end of the shaft is connected with the generator for the electrical power development.

Compressor:

The compressor takes air from the atmosphere and does work on it. So the air comes from the compressor with high pressure and temperature and goes to the combustion chamber.

Combustion chamber:

In the combustion chamber fuel is sprayed on the pressurized air so when the fuel comes in contact with the high temperature it will ignites. In the combustion chamber heat is produced by burning of the fuel and air. So when this air comes from the combustion chamber it becomes exhaust gas and goes in to the turbine chamber.

Turbine:

The exhaust gases expand in the turbine due which work is done on the rotor of the turbine as the shaft of is connected between the compressor and generator so some work is also transfer towards the compressor and the remaining work is invested on the generator side for the power production. The exhaust gases then go out of turbine through exit in the atmosphere. The temperature of the gases at the exit will be lower that the temperature at the combustion chamber.

So let us consider that 100 J of air enter in to the compressor, and comes out of the compressor ultimately 500 J which shows that the work is added by the compressor to the air. 400 J of work is added by the compressor to the air. Now in the combustion chamber heat is added to the air and comes out having energy 1000 J from the combustion chamber. These exhaust gases are allowed to expand in the turbine and after expansion the air comes out having energy 300 J from the exit. So in the remaining 700 J energy 400 J energy is requires by the compressor for its own working because it is investing 500 J work. The rest of the 300 J energy is used to rotate the generator for the development of electrical power.

This is called open loop system because air coming from the atmosphere going in to the system and go out of the system.

Close loop gas Turbine:

The component of the close loop gas turbine is similar to that of the open loop gas turbine but there is some difference the compressor compresses the air send it to the heat exchanger instead of combustion chamber. In heat exchanger the heat is added by the external agents, actual combustion does not takes place with air itself. It is added with the help of heat exchanger. Suppose that we are burning some coal so heat is develop which move in the exchanger and mix with air but actual combustion does not takes place with the air itself as like that of the open loop gas turbine. This hot air from the heat exchanger is allowed to expand in the turbine. So some of the work develop go back to the compressor for its running and some part is invested to the generator for developing electrical power. Now when the air come out from the turbine which has lower temperature. Now this air is pass through another heat exchanger where it only release the air to the atmosphere from the cooling heat exchanger. This air will go again to the compressor.

Classification of gas turbine:

The gas turbine may be classified on the basis of following factors:

On the basis of combustion process

- Continuous combustion or constant pressure type: the working principle is Joule or Brayton cycle

- The explosion or the constant volume type: the working principle is Atkinson cycle

On the basis of path of working substance:

- Open cycle gas turbine

- Closed cycle gas turbine

On the basis of action of expanding gases

- Impulse turbine

- Reaction turbine

On the basis of direction of flow

- Axial flow turbine

- Radial flow turbine

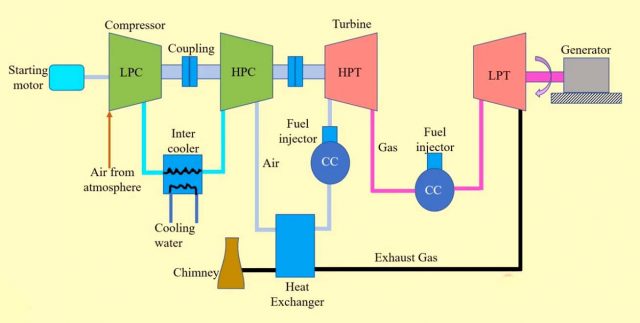

Working Layout of gas turbine power plant:

The gas turbine is not self-started so to start the gas turbine we need starting motor. The LPC which is low pressure compressor will suck air from the atmosphere where the pressure and temperature of the air will be increases. The compressed air is then send to the inter cooler system where the compressed air is cold with the help of cooling water which circulates in it. The compressed air is then send to the HPC which is high pressure compressor where the air is more compressed means pressure is increased. The high pressure compressed air then transfer to the heat exchanger where the exhaust gases are also present with the help of which the temperature of the compressed air are increased. The hot air is passed in to the CC combustion chamber when the temperature of the air is maximum then the burning of air occur easily. In the combustion chamber natural gas are used as fuel which when come in contact with the hot air ignition occurs. In some condition we also used spark plug for the burning process. The hot gases will be produce in the combustion chamber which will then transfer to the HPT high pressure turbine which will expend and will rotate the turbine. When the turbine start rotation as the shaft of turbine is connected with LPC and HPC they will also start rotation and the starting motor will stop. About 66 % of power is used for the working of the compressor and the remaining 34 % of power is used to rotate the shaft of the generator to produce electricity. From the HPT hot gases is again send to the CC combustion chamber where they again burn and their temperature increases more. These hot gases are then send to the LPT low pressure turbine. The generator shaft is coupled with the LPT which will starts rotation and generate electricity. The burn gases comes back to the heat exchanger which will heat up the compressed air coming from HPC. The exhaust gases are then left in the atmosphere with the help of chimney.

Application of Gas turbine:

Applications of gas turbine are as follow:

Turbojet engine:

Every turbojet engine and turbo propeller engine has a gas turbine. The turbine supplies power only to drive air compressor in the turbojet engine while in turbo propeller engine it may drive the propeller in addition to the compressor. The expansion of the gases may takes place in one turbine or in set of low pressure and high pressure turbine.

Marine field:

Gas turbine is also used in marine field. The power plant using the steam turbine requires boiler water storage tanks, and water distillation plant etc. but in gas turbine power plant we do not require these.

Super charging:

In super charging of IC engine a small gas turbine run by hot exhaust gases drives the super charger.

Railway engines:

The gas turbines have also entered in the field of railway engines. The electric company have successfully built a number of 4870 HP engines running on the gas turbo electric principle.

Electric Power generation:

Gas turbine power plant is now becoming popular. As compared to steam power station the gas turbine power station requires much less water. Therefore it is used at location where water is less available.

Industry:

Gas turbine is also employed for numerous industrial purposes e.g blast of air for blast furnace in steel industry, oil and other chemical industries.

Related Power Generation Articles:

Industrial Gas Turbine Working Principle

Magneto Hydro Dynamic Power Generation