Switched Reluctance Motor Construction and working with Block Diagram and Types

Table of Contents

Switched Reluctance motor:

In this article we will study about switched reluctance motor in short SRM, construction and working principle of switch reluctance motor, types of switch reluctance motor and the advantages, disadvantage and application of switch reluctance motor. The switched reluctance motor working is based on the variable reluctance principle. The rotating magnetic field is created with the help of power electronic switching circuit. The main concept of the switched reluctance motor is based on by changing the air gap between the rotor and stator. The switch reluctance motor sense the minimum reluctance. We can change the reluctance of the motor.

Reluctance is nothing but a resistance of the magnetic circuit means we can simply say that the reluctance is the property of magnetic material which supports the flow of flux on the principle of variable reluctance because in it reluctance varies due to the air gap. This means the rotor always try to align along the lowest reluctance path as the name suggests a switch or switching inverter is required for the operation of switched reluctance mode. So this is the definition of switch release motor.

Construction and working principle of Switched Reluctance motor:

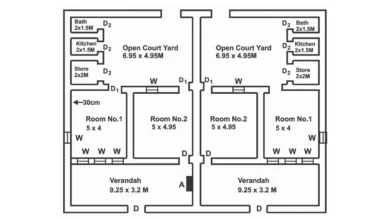

So firstly we discussed about the construction of SRM or the variable reluctance motor or switch reluctance motor has two different construction singling salient construction and doubly salient construction. Stator and rotor magnetic circuit are laminated to reduce the core losses in both type of switched reluctance motor. So first one is called the singly salient construction and second is doubly salient construction.

Singly salient construction:

So first one is a singly salient construction a singly salient construction switch reluctance motor comprised of non-salient stator and a salient two pole rotor. So the rotor do not have any winding wound over it but the stator has two phase windings as shown in figure.

No winding is placed in the rotor. It should be noted that in actual switch reluctance motor the number of phase winding on stator may be more than two. Since the rotor is of salient construction.

Inductance of the stator phase winding varies with the rotor position. The Inductance is minimum where the rotor axis and the stator phase winding axis coincide whereas it is maximum when both maximum quardature. When both the axis will be perpendicular to each other we will get maximum inductance and we will get minimum inductance when both axis concides with each other.

Doubly salient construction:

So next one is a doubly salient construction unlike singly salient type the stator of doubly salient switched reluctance motor is of salient construction and consists of four poles as shown a figure below. So this is the diagram for doubly salient construction stator as well as router is of salient construction but have two poles thus this type of the switched reluctance motor is a heteropolar motor where the number of stator and rotor poles are not same construction. The stator phase windings are concentrated winding these concentrated binding on the radially opposite poles are either connected in series or parallel to result into two phase winding on stator.

A doubly salient type switch to a reluctance motor or variable reluctance motor produce more torque as compared to singly salient type for the same size. Therefore a doubly switch reluctance motor is more common and widely used.

Working Principle of Switched Reluctance motor:

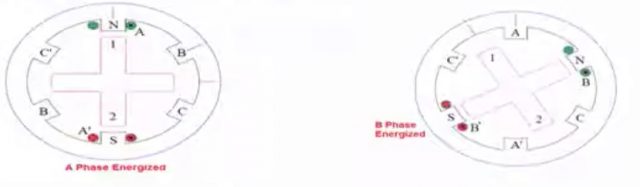

Next is a working principle of switched reluctance motor as we know that the magnetic flux have a tendency to flow through lowest reluctance path. Therefore the rotor always stands to align along the minimum reluctance path. This is the basic working principle of switched reluctance motor or variable reluctance motor. Therefore when stator phase winding is energized the rotor align along this face as shown a figure.

When stator phase winding is de-energized and the winding b is energized the rotor aligned itself along b phase as shown in a figure. This is the figure 2.

Similarly the rotor occupies a position along pace winding c when this phase is energized. So this direction is achieved by energizing the phase winding in an abc sequence if rotor rotating in anti-clockwise direction is required. The stator phase winding must be energized in a cb sequence. It must also be noted that a particular phase winding must be energized or de-energized in a synchronism with the rotor position. This means as soon as the rotor align along the a phase, b phase must be energized and a phase must be de-energized if the clockwise rotor rotation is required.

Block diagram of Switched Reluctance motor:

Next is the block diagram of Switched Reluctance motor SRM the dc input is connected to the driver or converter circuit and the output is connected to the motor. The main component of this is converter circuit and switched reluctance motor.

The dc input is connected to the driver or converter circuit and the output is connected to the motor. The rotor sensors feedback wire is connected to the controller circuit and it provides the position of the rotor with reference to the reference axis input job dc input then digital controller and the switch related mode. Finally the controller collects all the information and based on that reference will be given to the stator. The controller monitors the motor current to protect the motor from internal and external faults.

Torque developed by Switched Reluctance motor:

In switched reluctance motor torque is developed by the variation of the reluctance or permeance of air gap.

T= 1/2 i2 dLɵ/dɵ

Derivation of the torque produced:

V=IR+ dΨ/dt

V=IR+ (d(Li))/dt

V=IR+ (L di)/dt+i( dL/dɵ×dɵ/dt)

V=IR+ (L di)/dt+i( dL/dɵ ω)

Vi=i2 R+ (Li di)/dt+i2 ( dL/dɵ ω)

Types of Switched Reluctance motor:

The next topic is the types of switch reluctance motors based on the construction of the switch reluctance motor is divided into two categories:

- Linear switch reluctance motor: Single step stator and rotor

- Rotatory switched reluctance motor: More than one step stator and rotor.

This is the classification chart switch reluctance motor are divided into two categories rotatory SRM and linear SRM. Then linear SRM not classified and Rotatory SRM are further divided into two category:

- Radial field

- Axial field

An axial field is further classified into two category:

- Single stack SRM

- Multistack SRM

So these are the classification of switched reluctance motor.

Advantages and disadvantages of Switched Reluctance motor:

The next topic is advantages and disadvantages of switched reluctance motor. So the advantages of SRM is it does not require an external ventilation system as the stator and rotor slot projected or we can say that construction the airflow maintained between the slots amino the rotor does not have winding since therefore no need to keep the carbon brushes and the slip ring assembly since the absence of permanent magnet. Such motors are available at cheaper price. Simple three or two phase pulse generators is enough to drive the motor. The direction of the motor can be reversed by changing the phase sequence. Self-starting and does not require external arrangement. Starting torque can be very high without excessive in rush current. It has also high fault tolerance. Switch reluctance motor the phase losses do not affect the motor operation provide high torque and inertia ratio. High starting torque can be achieved in case of SRM.

Disadvantages of Switched Reluctance motor:

Next is the disadvantages of switch reluctance motor create torque ripple at high speed operation. The external rotor position sensor is required external rotor position sensors positions. So we can say that the noise level is high at the higher speed the motor generate harmonics to reduce this we need to install large size of capacitors. Since the absence of permanent magnet the motor has to design to carry high input current it increases the converter KVA requirement.

Applications of Switched Reluctance Motor:

Now the next is an application of SRM so it is used for demonstrating applications or domestic appliances such as:

- washing machine

- vacuum cleaner

- fans etc which application is switched.

Difference between Switched Reluctance motor and Stepper motor:

Energizing of the stator poles must be precisely timed to ensure that it occurred as the rotor pole is approaching alignment with the energized stator pole. Unlike stepper motor which can act for most purpose do operate in open loop mode. Switch reluctance motor require position feedback from the encoder or Hall Effect sensor to control communication of the stator current based on the precise rotor position. Switched reluctance motor has fewer poles and a larger stepping angle than the stepper motor. While stepper motor are typically chosen for positioning applications, where the step integrity and high resolution are important switch reluctance motor are used in applications, where the power density is a primary concern because switched reluctance motor have routers with no magnets or winding. So they have lower inertia and can therefore achieve higher acceleration and speed than the motor with permanent magnet rotor. Such as stepper motor the lack of magnets on the rotor provide the other benefit as well including the ability to withstand higher temperature means less cooling required and simple low cost construction than the permanent magnet stepper motor another difference between the switch reluctance motor and the stepper motors lie in the stator construction in the switched reluctance motor. There is no overlap of coils between successive faces in other words the phases are independent of one another. This means that if one or more phases fail, the motor will still be operable although with a reduced torque. The fact that both the stator and rotor have salient poles referred to as a doubly silent design means switch reluctance motor produce more audible noise than the stepper motor. So these are some comparative analysis between the SRM and stepper motor.