Types of Rotary Pumps, Screw Pump, Gear Pump, Lobe Pump, and Vane Pump

Table of Contents

Rotary Pumps, Description:

I am sure you know what is a pump and for what purpose a pump is used. It is a device that is used to move the fluids; it may be liquids or gasses by mechanical action. A pump has a casing provided with Inlet and Outlet openings. The fluid enters through the Inlet opening and leaves the pump through the Outlet opening. Now, this is the information that I think everyone knows. Because these things you will find in all types of Pumps.

Pumps are available in different shapes and sizes. Some pumps are low-cost while some are really expensive. Some are designed to be used in houses while some are designed to be used in industries. In this article, I will explain 4 different types of Rotary Pumps.

Amazon Purchase Links:

*Please Note: These are affiliate links. I may make a commission if you buy the components through these links. I would appreciate your support in this way!

There are 4 types of Rotary Pumps:

- Screw Pump

- Gear Pump

- Lobe Pump

- Vane Pump

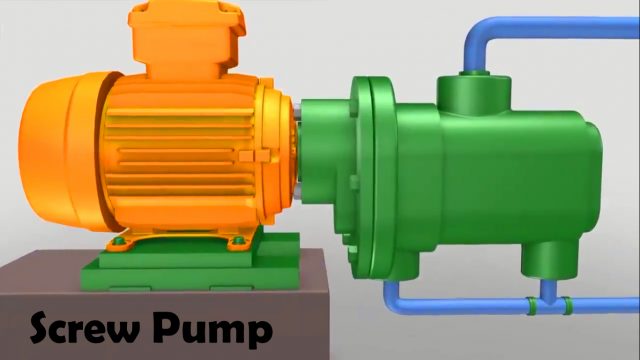

Screw Pump:

This is a Screw Pump. It is intermeshing of the of the threads on the rotors and the closed fit of the surrounding housing that creates one or more sets of moving seals in a series between the pump inlet and outlet.

These sets of seals or locks as they are sometime referred to act as a labyrinth and provide the screw pump with its positive pressure capability. The successive sets of seals for fully enclosed cavities, it moves continuously from Inlet to Outlet. These cavities are specially designed in a way to trap the liquid at the Inlet and carry it along to the Outlet providing a smooth flow.

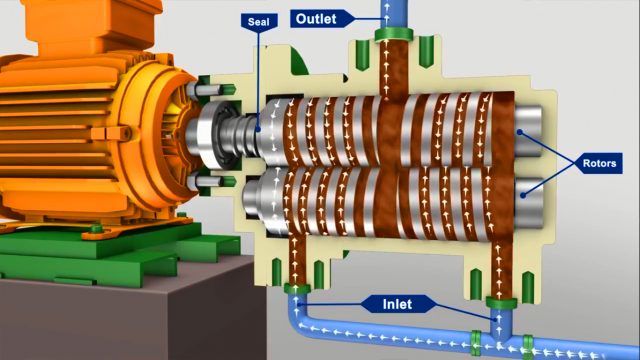

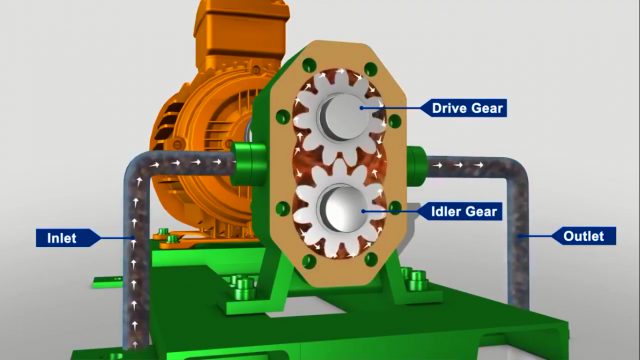

Gear Pump:

The Pump is so need because it has two gears that are side by side or external to each other.

In the picture above, you can clearly see this Gear Pump has two Gears. One Gear is called the Drive Gear while the other Gear is called as the Idler Gear. The Idler Gear is driven by the Drive Gear which is driven by a Motor. The direction of rotation of the Idler Gear is opposite to the direction of rotation of the Drive Gear. The liquid when enters into the chamber is trapped in the Gear teeth spaces between the housing bore and the outside of the Gears, is transferred from the Inlet side of the Gear Pump to the Outlet side of the Gear Pump. The meshing of the Gears of the discharge side of the Pump forces the liquid out of the Pump and into the discharge piping.

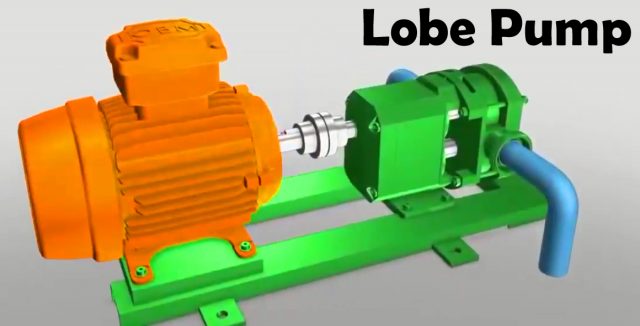

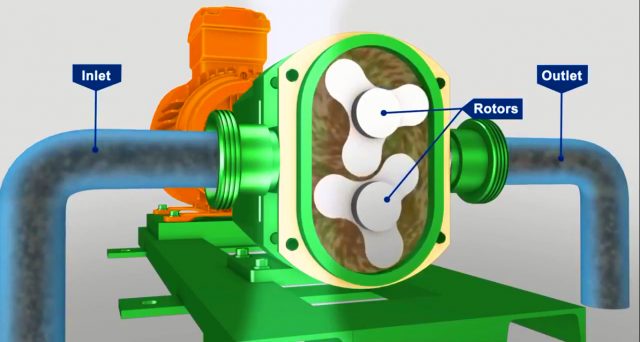

Lobe Pump:

The Lobe pump receives its name from the rounded shape of the rotors radial surfaces. This allows the rotors of the Lobe Pump to be continuously in contact with each other as they rotate.

Lobe Pumps can be single or multiple Lobe Pumps designed in way to remain continuously in contact and carry fluid between their rotor lobes in much the same way as gear pump does.

Just like the Gear Pumps, however, neither the number of lobes nor their shape permits one rotor to drive the other, and so all true Lobe Pumps require timing gears.

Vane Pump:

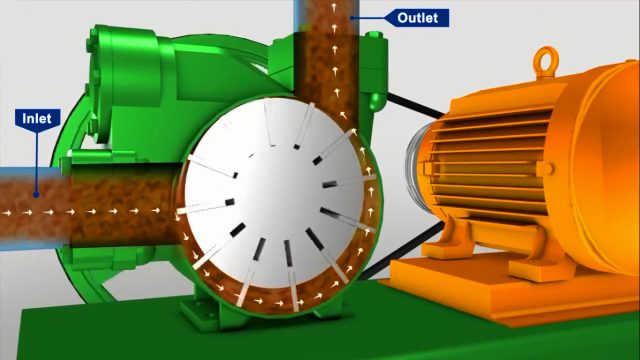

Vane Pump includes a rotating cylinder containing equally spaced radial pistons arranged radially around the cylinder center line.

The pistons are provided with the springs on the back, which pushes the pistons against the inner surface of an encircling stationary ring mounted eccentric to the cylinder. The piston drives fluid during half a revolution and drive fluid out during the other half. The greater the ring eccentricity is the longer the piston stroke and the more fluid they transfer.

Rotary Pumps Applications:

- Gear Pumps handle more viscous fluids

- Sliding Vane Pump suits both viscous and non-viscous fluids

- Sliding Vane Pumps cannot handle dirty or gritty liquids

- Vane Pumps are ideal for low-viscosity and non-lubricating liquids

- Sliding Vane Pumps are used for vacuum services

- Lobe Pumps are used in food and beverage processing

- Lobe Pumps can handle both low and high viscosity fluids

For video tutorials, visit my YouTube channel “Electronic Clinic”

- Screw Pump

- Gear Pump

- Lobe Pump

- Vane Pump